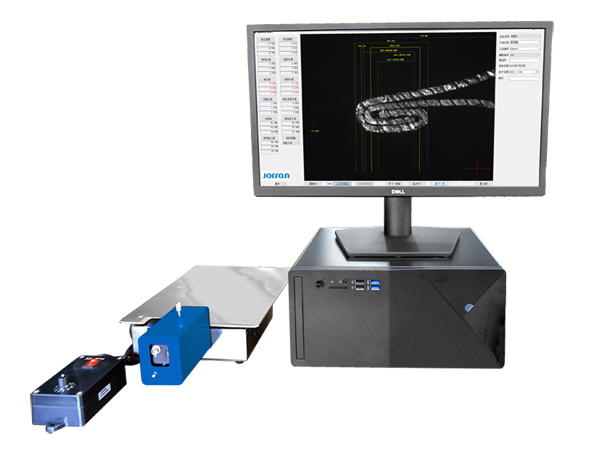

Double Seam Projector

Our A1.2 DT-W intelligent double seam projector consists of a projector and computer that is specially designed for detection processes on the metal can body’s seam structure. We also apply modern video technology and a specialized optical system on our metal can seam detector.

Our double seam projector achieves digital processing on the metal can body’s seam structure and displays that data on screen, speeding up the detection process carried out by the technical operating procedures.

1. Detection of sizes on the metal can body’s seam structure

Seam width "W"

Seam thickness "T"

Body hook length "BH"

Cover hook length "CH"

Countersunk degree "C"

Gap length "GL"

Overlap length "OL"

Overlap rate "OL%"

Coverhook involved degree "CB%"

Body hook involved degree "BB%"

Tightness "TR%"

Joint cover hook complete rate "JR%"

The OL%, CB%, BB%, TR%, and JR% are all automatically calculated by the computer. The material thickness at the seaming can also be detected.

2. Automatic identification

Our video seam monitor can automatically identify the test results to determine if the value is qualified.

3. Data Conversion

The data generated by our double seam projector can convert back and forth between metric and non-metric measurements.

4. Storage

Our seam inspection system can create a file for resulting data and seam images, and store them in the database of the operating procedure.

5. Output

The test report can be printed out, and the test report data and images can be saved, and sent out over the internet.

6. Mathematical Analysis

The computer on our double seam projector can process data using mathematical data processes, including histograms, statistics of attributes on the test data, and mathematical analysis of dispersion. The analysis report can then be saved or printed out.

| Amplification Ratio | 30x |

| Field of Horizontal View (Optional) | 6 mm-8 mm |

| Display Resolution | 0.001mm |

| Detection Accuracy | 0.01 mm |

| Testable Diameter of Cans | 30mm-300mm |

| Power | 220V, 50Hz |