Home » Products » 3-Piece Can Production Line » 40-50CPM Automatic Tinplate Pail and Bucket Production Line

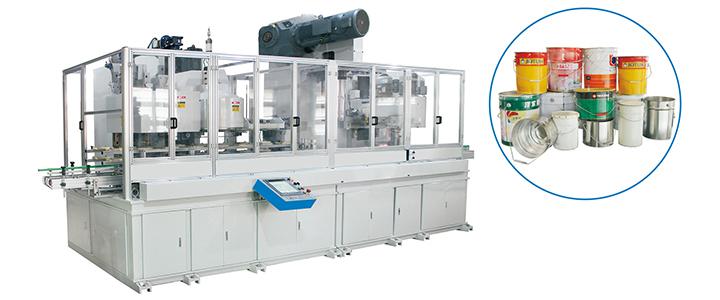

40-50CPM Automatic Tinplate Pail and Bucket Production Line

Features

The 40-50CPM automatic tinplate pail and bucket production line adopts Siemens or Lenze’s motion controller, and cams for transmission, can conveying and can holding. The speed & working height can be adjusted by HMI (human-machine interface). Meanwhile, since it is outfitted with protection device, as well as rotary flanging and servo controlled U turning system, the production process could run smoothly & safely. Besides, when compared with others, the production line is more energy saving and environment friendly.

Production Process

Vertical delivery of cans → Rotary flanging →Bottom seaming → U-turning of cans → Expanding → Pre-curling → Curling & Beading

Main Technical Parameters

| Output | 40-50 pieces per minute |

| Air pressure | Not lower than 0.6Mpa |

| Connection height | 1000±20mm |

| Overall weight | Approx.19T |

| Dimension(L×W×H) | 8000×1750×3100mm |

| Voltage | Three-phase four-wire 380 V(or customized) |

| Overall power | Approx.30KW |

Inquiry Form