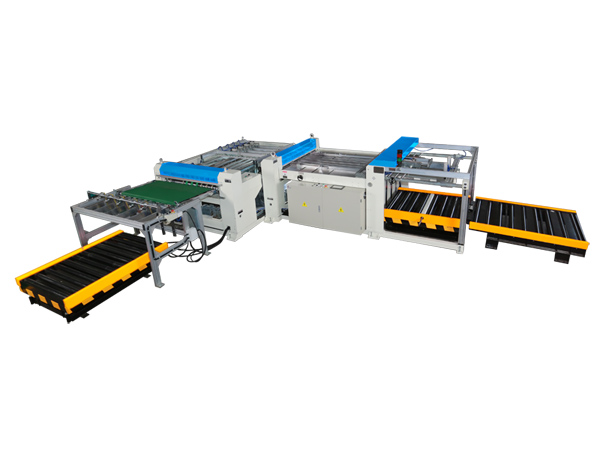

Duplex Slitter

The duplex slitter is one of the most important pieces of equipment in a 3-piece can production line. The slitting machine is used to cut the tinplate into can body blanks in the correct size. Our duplex slitter is high quality and an optimal solution for your metal packaging factory.

Jorson's duplex splitter is specifically designed for canned food factories and empty can manufacturing plants. It is also suitable for slitting sheet metal into similar sizes for other industries, and can meet the demanding requirements of a high-speed resistance welding machine.

1. Our duplex slitter takes the tinplate with a vacuum, and uses a gear motor to automatically control the height of the tin plate.

2. The wheel cutter's rotation is stable and has a sleep operation, allowing the can body blanks to be uniform in size.

3. The single adjuster ensures the right angle both vertically and horizontally.

4. Our duplex slitter is simply designed and is easy to maintain or replace.

5. The oil pressure wheel cutter holder and the tungsten steel blade can be installed, but are not required.

6. The duplex slitter is equipped with Mitsubishi electrical control components and Yuken hydraulic components, offering high accuracy and stability, easy operation and easy adjustment.

| Model | |

| Max. feeding size | 1200mm × 1200mm |

| Min. feeding size | 600mm × 600mm |

| Slitting thickness | 0.12-0.50mm |

| Slitting speed | 30SPM |

| Slitting diagonal tolerance | ≤0.05mm |

| Max. 1st slitting quantity | 6 strips |

| Max. 2nd slitting quantity | 18 strips |

| Power consumption | 12 Kw |